Expertise: Cloud-based software solution in Big Data Predictive Maintenance

Founded: 2015

Team: 11-50

HQ: Haifa, Israel

Management: Eitan Vesely

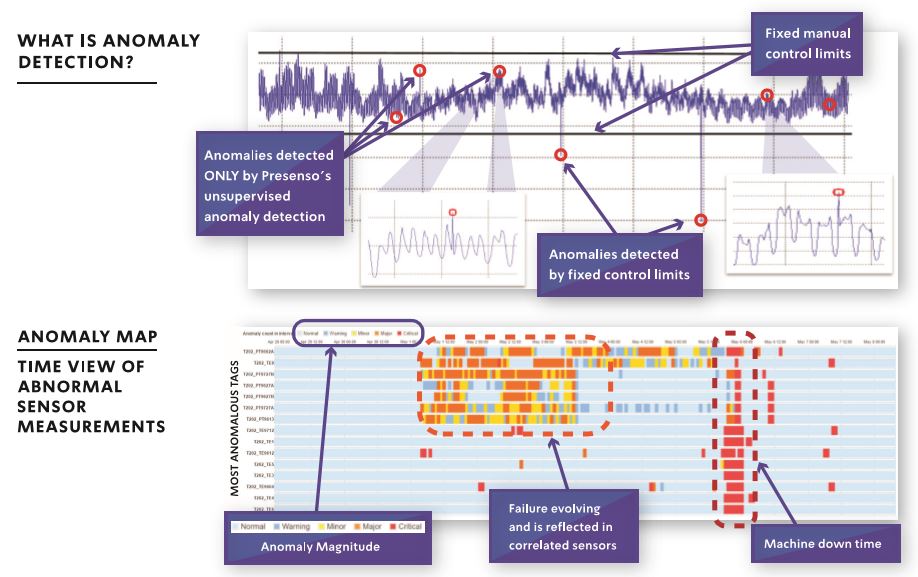

The Presenso solution is machine agnostic and requires no in-advance human input or expert knowledge. Adaptive algorithms replace rule-based SCADA monitoring to automatically detect abnormal measurements in machine sensor behavior. Early prediction of machine failure is generated hours to days before traditional monitoring systems recognize the issue, giving time for pre-failure proactive asset maintenance.

Our Product: A fully-automated and unsupervised monitoring solution for industrial assets failure prediction

Presenso continously streams big data to the cloud that is generated by all existing sensors in industrial machines. Artificial Intelligence algorithms analyze each piece of sensor data in the cloud and in real time. Presenso is sensor agnostic and monitors all signal data without the need for manually setting control limits or any other human input.

After the detection of anomalies in all the asset’s signals, correlations and pattern detections between signals are perfomed in order to later present the operators with the exact sequence of abnormal events detected. Failure alert includes information on remaining-time-to-failure and groups of correlated sensor abnormalities. Valuable information significantly helps in tracking the failure origin.

The Presenso anomaly detection helps to predict machine failure. (Image source: Presenso)

Key components:

1. Real time analysis of sensor data

Presenso continously streams big data generated by all existing sensors in industrial machines. Artificial Intelligence algorithms analyze each piece of sensor data in the cloud and in real time. There are no limits to the number of sensors that are monitored. While current SCADA systems use manually set and fixed control limits to monitor only a handful of important sensors. Presenso monitors all of them, even if they number in the thousands per machine.

2. AI driven anomolies intercepton

Algorithm driven monitoring replaces rule-based SCADA alerting systems that leaves many anomalous measurements undetected. Presenso is sensor agnostic and monitors all signal data without the need for manually setting control limits or any other human input. Unsupervised detection reduces the need for high-cost labor intensive intervention.

3. Contextualization of machine behavior

Detecting abnormal sensors measurements is not enough. After the detection of anomalies in all the asset’s signals, correlations and pattern detections between signals are performed in order to later present the operators with the exact sequence of abnormal events detected. This turns into valuable information and assists in tracing back to failure origin.

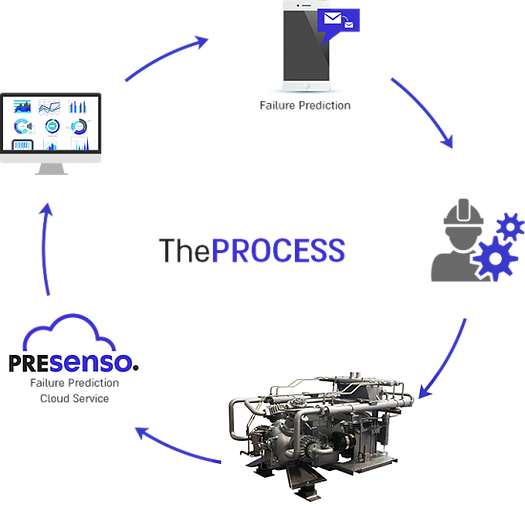

4. Failure prediction based on adaptive learning

Our unique algorithm predicts machine failure based on anomalies intercepted in sensor behavior and the correlation detected between them. When failure is predicted, the system sends an alert to factory operations and maintenance teams. This alert includes an estimation of remaining-time-to-failure and groups of failure-related correlated sensor abnormalities.

The cycle of anomaly detection, correlation, prediction and prescription. (Image source: Presenso)

Different views

a) Global overview

Compare sites performance

- high level real-time report showing a global overview of your operation

- presenting the performance and probability for a failure in all sites

- easily compare site performance

b) Factory view

Compare machine behaviour

- View all machines operating in your facility on one screen

- get clear visual indication of machine performance

- compare machines with adjacent ones in the fleet

- start investigating in case a machine is marked as prone to fail

c) Machine view

Technical view of suspicious machine behaviour

- Low level drill down into a single machine dashboard

- List of top anomalous sensors

- Mapping off all abnormal sensor measurements detected

- Cross-sensor correlations

d) Sensors view

Low level sensor value

- Novel and unique method to visualize Big Data

- All sensors operating in the machine are available for low level troubleshooting on one screen

Key benefits:

- reduces unscheduled downtime

- prevents machinery breakdown before it occurs

- uses big data without the need for human intervention

- replaces partially effective rule-base monitoring

- agnostic to sensor type, equipment type or asset age

- easy and quick root cause analysis of historical event

- analyzes ALL sensors without a need to select a patial list of high-priority senors

Our Presenso CEO Eitan Vesely (Image source: Presenso)

Contact

Presenso

Matam Industrial Park

Haifa, 3190500 Israel

Phone: +972 4 982 1199

E-Mail: info@presenso.com

Web: www.presenso.com

Social Media: Linkedin

Presenso

Why not share this article?